News

Highly Efficient Energy-saving Heat Pump Offers a New Choice for Fish Farms Against Cold Weather

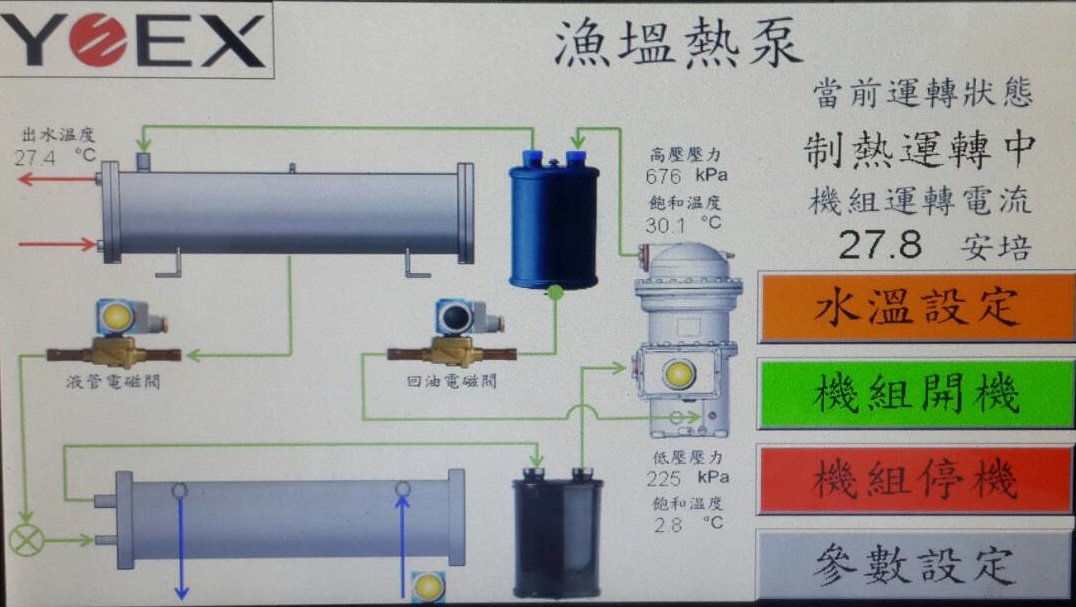

Since the Council of Agriculture (COA) launched the AGTECH Program for encouraging enterprises to invest in Agricultural R&D actively in 2007, it has provided subsidies to many enterprises to carry out the commercialization of technology successfully. Fusheng Co., Ltd., which runs the Technology Development of Warming Rquipment for Aquaculture project from 2017 to 2018, developed a heat pump system for aquaculture and achieved preliminary results after field tests. The pump presents a highly efficient energy consumption compared with the traditional boiling heating system. Its heat transfer coefficient can reach the target of the Coefficient of Performance (COP) greater than or equal to 6 while raising more than 2 Celsius degrees (⁰C) of temperature in the pond. In the future, field tests will be conducted regularly to evaluate the water quality and weather resistance in the environment so as to assist the farmers in cold weather protection and prevent the damage caused by cold temperature.

Heat conduction in fish farms effectively improves the survival rate of milk fish

The COA pointed out that due to climate change, strong cold currents always threaten the livelihood of the fish farmers. Whenever the cold front invades, heating measures need to be taken to raise the water temperature. The solution mainly involves using low-temperature refrigerant from evaporators to absorb the heat in fish farms, then heat up the water in winter ditches or cold buffer zones through heat exchange from condensers by utilizing compressed high-temperature refrigerant, thus raising water temperatures in partial areas of the fish farm. Results from field tests demonstrate that when temperature drops to 8⁰C, the culture ponds that are unprotected by any prevention measures show a milk fish survival rate of only 50%. As for the ponds using Fusheng heat pump systems are able to maintain an average temperature of 12⁰C and above, which show a survival rate of up to 99%. In addition to its principal function of manipulating water temperature, the heat pump can also carry microbubble devices to provide heat and aeration simultaneously, thus creating water convection. The company may have found the solution to combat the problem that plagued this industry around the world for a long time, and therefore become the guardian of aquaculture against cold weather.

The COA further explained that the heat pump invented by Fusheng Co., Ltd. was applied to aquaculture, and became the perfect instance of collaboration between industry and agriculture. Designed to be in line with the smart device trend, the said heat pump can also be upgraded for remote monitoring and wireless transmission. Through the project, the heat pump is confirmed to increase the temperature of specific areas. Nevertheless, the cost of the equipment is rather high at this stage and requires further adjustments as well as field tests to bring down the cost and meet commercialization requirements. Currently the company has acquired the invention patent for water temperature regulation system for aquaculture as well as utility model patent for water temperature regulating device for fish farm to protect their technological property. In addition, in order to enhance the device’s application value, its R&D team has utilized the invention on quality aquaculture such as the breeding of high-commercial-value shells like hard clam larvae, crown conchs, and areola babylon. It is through such model that the cost and benefit could be balanced and through the dual function of refrigeration and heating, the technology could be applied to fish species with high commercial value. The company welcomes all inquiries for potential industrial cooperation.

Encourage companies to acquire key technology and commercialize R&D results

The COA stated that the AGTECH Program has completed 74 projects since its inception in 2007. An estimate based on the accumulated result shows that each NT Dollar that the government spent in subsidy would in turn result in an average of 1.35 NT Dollar direct investment from the industry and yield 7.22 NT Dollar worth of production value. Moreover, the derivative investment that comes from the enterprises is over NTD 1.6 billion. The Council would continue to promote the AGTECH Program to encourage more innovative R&D, and connect the academic research results with innovative R&D, which in turn could be transferred to industry and commercialized worldwide.